型號: 21915812281280

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

從頭開始設計我們的每一件電動釀造設備,使我們能夠引入更高水平的過程控制,靈活性和性能。每一個細節都經過精心的思考和完善。

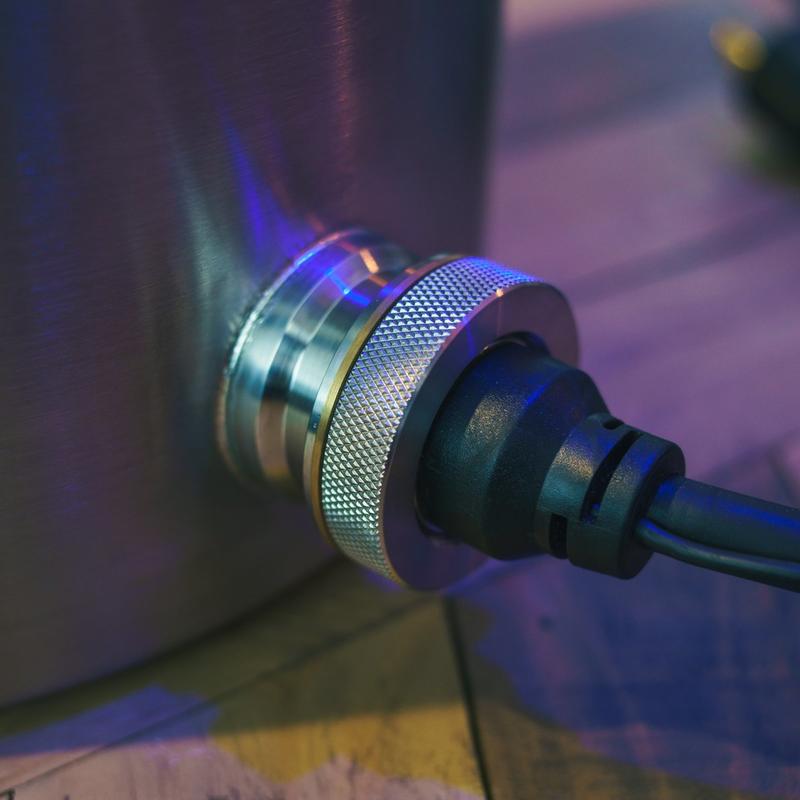

通過使用我們定制設計的元件和eKettle元件端口實現靈活性,可以輕鬆移除元件進行清潔。此外,我們沒有滿足於普通的,現成的直線或波紋元素。相反,我們設計了一個低瓦特密度光環元件,特別是相應的水壺體積。除了促進有效的漩渦和錐形錐形成之外,這種設計更適合於在整個水壺中均勻分佈熱量。採用Incoloy 800合金製成,我們的元素比標準不銹鋼具有更高的耐熱性和抗氧化性。

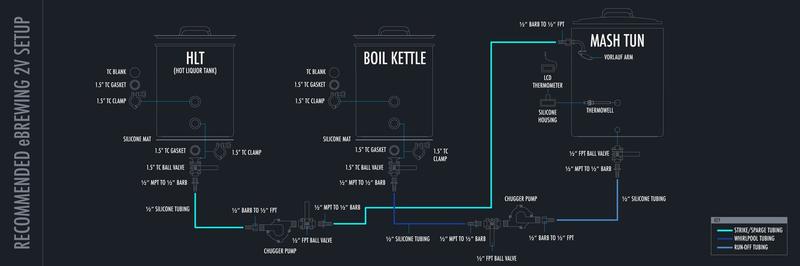

最後,性能對我們設計的每件事都非常重要。我們對10加侖和20加侖尺寸的元件和控制器進行了調整,以最大化標準的240 VAC,30安培住宅電路。因此,匝道時間很快,這可以縮短釀造日。我們還希望將一些最新的產品改進與我們的一些經典技術相結合。因此,我們決定使用帶有全焊接TC配件的水壺,以及我們古老的trub dam,現在與TC球閥配對。即使是小巧的美學細節也不會被忽視,例如從前到後的手柄定位,以實現更緊湊的臥式啤酒屋佈局。或者將PT100溫度探頭集成到加熱元件底座中,這減少了對專用熱電偶套管端口的需求。

Designing every piece of our electric brewing equipment from scratch has enabled us to introduce a new level of process control, flexibility, and performance. Every detail has been carefully thought through and refined.

Flexibility is realized through the use of our custom-designed element and eKettle element port, which allows for easy removal of the element for cleaning. In addition, we didn't settle for a common, off the shelf straight or ripple element. Instead, we designed a low watt density halo element, specifically sized to the corresponding kettle volume. This design is better suited to distributing heat evenly throughout the kettle, in addition to fostering an effective whirlpool and trub cone formation. Crafted from Incoloy 800 alloy, our element carries a higher resistance to heat and oxidation than standard stainless.

Lastly, performance is deeply important to everything we design. We sized the element and controller in both 10 and 20 gallon sizes to maximize a standard 240 VAC, 30 amp residential circuit. As a result ramp times are quick, which work to shorten the brew day. We also wanted to blend some of our latest product enhancements alongside some of our classic tech. So we decided on a kettle with fully welded TC fittings, alongside our venerable trub dam, which is now paired with a TC ball valve. Even small aesthetic details were not overlooked, such as a front to back handle orientation for a more compact horizontal brewhouse layout. Or integrating a PT100 temperature probe into the heating element base, which alleviates the need for a dedicated thermowell port.