型號: 21915846962104

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

FTS臨時控制器現在作為捆綁選項出售

同類最佳的30 psi最大工作壓力

全焊接TC法蘭

組合3“TC幹跳,CIP和PRV端口

3“ 帶 PRV的TC帽

1.5“TC碳纖維石頭,帶3/8”球閥

1.5“TC吹掉手杖,焊接吹臂安裝

1.5“TC至½”球閥,用於吹掉手杖

1.5“TC pro衛生型壓力表

1.5“TC pro衛生取樣閥

1.5“TC熱電偶套管,帶LCD溫度計

6“TC蓋子,帶有完全焊接的冷卻器盤管

氯丁橡膠絕緣夾克

蝶閥與耙臂

不銹鋼下架

可調腳

304不銹鋼結構

對於15.5加侖批次

43.5“高(地板到壓力表)

30 PSI最大壓力,15 PSI工作壓力

19.0“最大寬度

我們推出了我們的Unitanks系列,帶有納米級的1 bbl Unitank,現在我們已經為家庭釀酒商提供了專業Unitank的所有功能。100%TC連接,用於溫度控制和碰撞的蓋式浸入式冷卻器盤管以及容器內碳酸鹽的能力使Unitank成為市場上最好的發酵罐。

一些照片屬於1 bbl Unitank。

在所有完全焊接的TC連接和專業功能之上。該裝置使釀酒師能夠使用碳化石石在24小時內快速吸收啤酒,同時精確監測頭部壓力。迄今為止的功能僅適用於家用釀酒商的Ss Brite Tank。然後進行真正的加壓和封閉轉移到服務容器,桶,反壓瓶灌裝機或罐裝機。與公開轉移相比,封閉轉移顯著降低了氧化機會。

較高的壓力限制還使用戶能夠將啤酒直接從容器中過濾成上述包裝方法之一。最後,添加了一個噴射閥的單元箱也使釀造者能夠在壓力下發酵,這種情況越來越受歡迎。同樣地,釀造者可以使用活性發酵剩餘的最後幾個重力點來自然地碳酸化他們的啤酒而不是強制碳酸鹽。增加的功能集和靈活性是專業釀酒商在釀造和包裝過程中使用單元庫的原因。

我們將所有產品設計為安全性作為首要考慮因素,這也是為什麼這些容器在推薦的工作壓力下以4倍進行大力測試的原因之一。一旦完成第一個生產黃金樣品的製造,該單元將被送到實驗室,在那裡進行一系列測試以確保船舶符合我們的嚴格標準。這些測試由SGS在實驗室環境中進行,SGS是檢驗,驗證和測試認證的全球領導者。

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

FTS臨時控制器現在作為捆綁選項出售

同類最佳的30 psi最大工作壓力

全焊接TC法蘭

組合3“TC幹跳,CIP和PRV端口

3“ 帶 PRV的TC帽

1.5“TC碳纖維石頭,帶3/8”球閥

1.5“TC吹掉手杖,焊接吹臂安裝

1.5“TC至½”球閥,用於吹掉手杖

1.5“TC pro衛生型壓力表

1.5“TC pro衛生取樣閥

1.5“TC熱電偶套管,帶LCD溫度計

6“TC蓋子,帶有完全焊接的冷卻器盤管

氯丁橡膠絕緣夾克

蝶閥與耙臂

不銹鋼下架

可調腳

304不銹鋼結構

對於15.5加侖批次

43.5“高(地板到壓力表)

30 PSI最大壓力,15 PSI工作壓力

19.0“最大寬度

我們推出了我們的Unitanks系列,帶有納米級的1 bbl Unitank,現在我們已經為家庭釀酒商提供了專業Unitank的所有功能。100%TC連接,用於溫度控制和碰撞的蓋式浸入式冷卻器盤管以及容器內碳酸鹽的能力使Unitank成為市場上最好的發酵罐。

一些照片屬於1 bbl Unitank。

在所有完全焊接的TC連接和專業功能之上。該裝置使釀酒師能夠使用碳化石石在24小時內快速吸收啤酒,同時精確監測頭部壓力。迄今為止的功能僅適用於家用釀酒商的Ss Brite Tank。然後進行真正的加壓和封閉轉移到服務容器,桶,反壓瓶灌裝機或罐裝機。與公開轉移相比,封閉轉移顯著降低了氧化機會。

較高的壓力限制還使用戶能夠將啤酒直接從容器中過濾成上述包裝方法之一。最後,添加了一個噴射閥的單元箱也使釀造者能夠在壓力下發酵,這種情況越來越受歡迎。同樣地,釀造者可以使用活性發酵剩餘的最後幾個重力點來自然地碳酸化他們的啤酒而不是強制碳酸鹽。增加的功能集和靈活性是專業釀酒商在釀造和包裝過程中使用單元庫的原因。

我們將所有產品設計為安全性作為首要考慮因素,這也是為什麼這些容器在推薦的工作壓力下以4倍進行大力測試的原因之一。一旦完成第一個生產黃金樣品的製造,該單元將被送到實驗室,在那裡進行一系列測試以確保船舶符合我們的嚴格標準。這些測試由SGS在實驗室環境中進行,SGS是檢驗,驗證和測試認證的全球領導者。

We introduced our Unitanks with the nano-sized 1 bbl Unitank, now we've made all the features of a professional Unitank available to the home brewer as well. 100% TC connections, lid mounted immersion chiller coil for temp control and crashing, and the ability to carbonate in-vessel make the Unitank the very best fermenter on the market.

Fully welded TC flanges

Combination 3” TC dry hop, CIP, and PRV port

3” TC cap with PRV

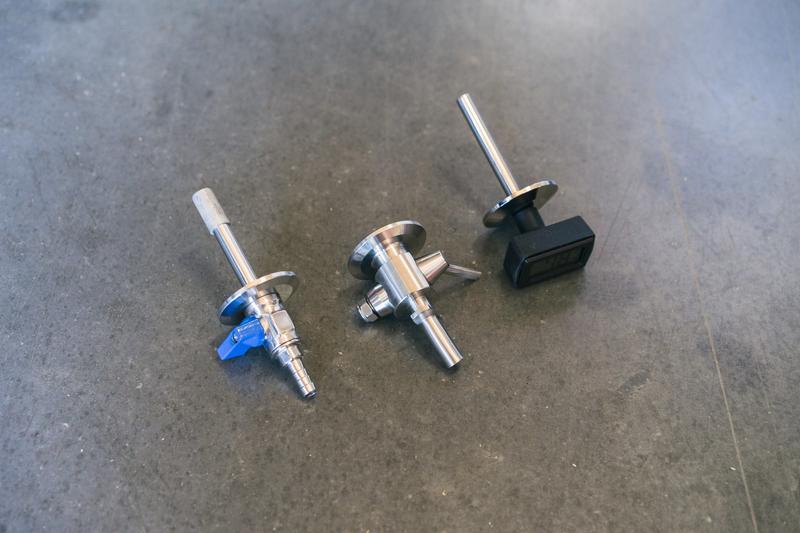

1.5” TC carb stone with 3/8” ball valve

1.5” TC blow off cane with welded blow off arm mount

1.5” TC to ½” ball valve for blow off cane

1.5” TC pro sanitary pressure gauge

1.5” TC pro sanitary sampling valve

1.5” TC thermowell with LCD thermometer

6” (8" on One bbl) TC lid with fully welded chiller coil

Neoprene insulation jacket

Butterfly valves with racking arm

Stainless lower shelf

Adjustable feet

On top of all the fully welded TC connections and pro features. The unitank gives the brewer the ability to quickly carb beer in under 24 hours using the carb stone, while precisely monitoring head pressure. Features that until now were only available on our Ss Brite Tank for home brewers. Then perform a true pressurized and closed transfer to a serving vessel, keg, counter pressure bottle filler, or canning machine. Closed transfers significantly reduce the chances of oxidation when compared to open transfers.

Higher pressure limits also gives the user the ability to filter beer directly out of the vessel into one of the aforementioned packaging methods. Lastly, a unitank with the addition of a spunding valve also gives the brewer the ability to ferment under pressure, which is gaining in popularity. In that same vein, the brewer can use the final few gravity points left of active fermentation to naturally carbonate their beer instead of force carbonate. The added feature set and flexibility is why pro brewers use unitanks in their brewing and packaging processes.

We introduced our Unitanks with the nano-sized 1 bbl Unitank, now we've made all the features of a professional Unitank available to the home brewer as well. 100% TC connections, lid mounted immersion chiller coil for temp control and crashing, and the ability to carbonate in-vessel make the Unitank the very best fermenter on the market.

Some photos are of the 1 bbl Unitank.

FTSs temp controller now sold as a bundled option

Best in class 30 psi max operating pressure

Fully welded TC flanges

Combination 3” TC dry hop, CIP, and PRV port

3” TC cap with PRV

1.5” TC carb stone with 3/8” ball valve

1.5” TC blow off cane with welded blow off arm mount

1.5” TC to ½” ball valve for blow off cane

1.5” TC pro sanitary pressure gauge

1.5” TC pro sanitary sampling valve

1.5” TC thermowell with LCD thermometer

6” TC lid with fully welded chiller coil

neoprene insulation jacket

Butterfly valves with racking arm

Stainless lower shelf

Adjustable feet

304 Stainless construction

For 15.5 gallon batches

43.5" Tall (floor to pressure gauge)

30 PSI max pressure, 15 PSI operating pressure

19.0" Max width

On top of all the fully welded TC connections and pro features. The unitank gives the brewer the ability to quickly carb beer in under 24 hours using the carb stone, while precisely monitoring head pressure. Features that until now were only available on our Ss Brite Tank for home brewers. Then perform a true pressurized and closed transfer to a serving vessel, keg, counter pressure bottle filler, or canning machine. Closed transfers significantly reduce the chances of oxidation when compared to open transfers.

Higher pressure limits also gives the user the ability to filter beer directly out of the vessel into one of the aforementioned packaging methods. Lastly, a unitank with the addition of a spunding valve also gives the brewer the ability to ferment under pressure, which is gaining in popularity. In that same vein, the brewer can use the final few gravity points left of active fermentation to naturally carbonate their beer instead of force carbonate. The added feature set and flexibility is why pro brewers use unitanks in their brewing and packaging processes.

We design all of our products with safety as an overarching concern, which is one reason why these vessels are vigorously tested at 4x their recommended operating pressure. Once the fabrication of the first production golden sample is complete, the unit is sent to a lab, where it undergoes a series of tests to insure that the vessel conforms to our strict standards. These tests are performed in a lab environment by SGS, a global leader in inspection, verification, and testing certifications.