型號: 21915867069239

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

請洽代理商業務詢問

3個加熱元件(Boil Kettle,HLT和RIMS)

在Boil加熱元件周圍的內部Calandria

切線漩渦端口

整個閥門樹不銹鋼硬頂

Perlick Style取樣閥

可拆卸的CIP臂

噴射環

Combo Vorlauf / Strike水填充端口

專用的下管腿

採用歐姆龍PID控制器的比例加熱元件控制與動態電壓可調節性相結合

主控制面板帶有HLT,Mash,Kettle和熱交換器溫度讀數

專用泵控制開關

雙推車安裝電氣服務面板

船完全組裝並準備釀造

1桶最終批量

20%水壺頂部空間

2.5毫米水壺壁厚

2B磨完

1“工藝管道

1“ID蝶閥,視鏡和TC墊圈

1平方米換熱器表面積

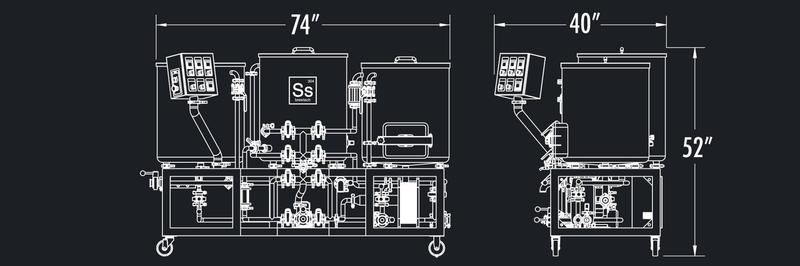

74“寬x 52”高x 40“深

208v或240v單相 –60安培專用電路 – 通常用於住宅和輕型商業建築。

如果您不確定,請諮詢您的公用事業提供商,以核實您所在地區可用的電氣服務類型。

訂購Ss產品請先與賣家討論了解需求及功能再行下單

或可谷哥Ss釀酒科技台灣總代理了解產品詳細功能及規格

請洽代理商業務詢問

3個加熱元件(Boil Kettle,HLT和RIMS)

在Boil加熱元件周圍的內部Calandria

切線漩渦端口

整個閥門樹不銹鋼硬頂

Perlick Style取樣閥

可拆卸的CIP臂

噴射環

Combo Vorlauf / Strike水填充端口

專用的下管腿

採用歐姆龍PID控制器的比例加熱元件控制與動態電壓可調節性相結合

主控制面板帶有HLT,Mash,Kettle和熱交換器溫度讀數

專用泵控制開關

雙推車安裝電氣服務面板

船完全組裝並準備釀造

1桶最終批量

20%水壺頂部空間

2.5毫米水壺壁厚

2B磨完

1“工藝管道

1“ID蝶閥,視鏡和TC墊圈

1平方米換熱器表面積

74“寬x 52”高x 40“深

208v或240v單相 –60安培專用電路 – 通常用於住宅和輕型商業建築。

如果您不確定,請諮詢您的公用事業提供商,以核實您所在地區可用的電氣服務類型。

When we began designing the 1 bbl Brewhouse we knew we didn't want to simply scale up our home equipment . Instead, we took everything we've learned designing, operating, and executing full size professional brewhouses around the country and scaled it down. The result of this approach is the industry’s first professional grade nano brewhouse. Engineering better beer. That's what we do.

Systems will be shipped fully assembled palletized LTL with liftgate service.

We have designed the heat sources and electrical framework of the 1 BBL brewhouse to enable the brewer precise control over each temperature and process. At the core of that objective are independent heating elements for each vessel, allowing the user to dial in the perfect strike and sparge temp in the HLT, sustain or step mash temps through the integrated RIMS tube, or modulate the perfect rolling boil via the proportional heat control in the kettle.

Drawing from the brewer-centric design of our pro brewhouses lead us to the key design feature of this system, the valve tree. Placing all the critical process valves in one central location makes the brew day intuitive and enjoyable. The control panel is a scaled down version from our larger pro brewhouses. The entire brewhouse is built upon a network of sanitary welded and fully hard piped TC connections. The integral hard piping matched with a fully welded frame provides a fit and finish never before seen in a 1 bbl brewhouse.

Milled False Bottom & Grain-Out

You won't find a punched false bottom on any of the professional brewhouses we design, and we felt there was no place for one on the nano brewhouse. The precision milled false bottom allows for a faster vorlauf, clearer run off, and mitigates the risk of a stuck sparge. The pro inspired grain-out door allows for quick and easy clean up. Tip and dump, or scooping grain from the top of a mash tun are a thing of the past.

Full Sanitary Hard Piping with our Patent Pending Valve Tree

Milled Plate False Bottom with Grain Out Door

Rotatable Kettle pick-up tube

Electric heating elements for HLT, RIMS, and Internal Calandria

Frame-Mounted Chugger Max Sanitary Pumps and Plate Heat Exchanger

208v or 240v Single Phase - 60 amp Dedicated Circuit - Typically found in residential and light commercial buildings.

If you are unsure, check with your utility provider to verify the type of electrical service that is available at your location.

3 heating elements (Boil Kettle, HLT, and RIMS)

Internal Calandria around Boil heating elements

Tangential whirlpool port

Stainless hard pipping throughout with valve tree

Perlick Style sampling valve

Detachable CIP arm

Sparge ring

Combo Vorlauf/Strike water fill port

Dedicated underlet leg

Proportional heating element control with Omron PID Controllers combined with dynamic voltage adjustability

Main control panel with HLT, Mash, Kettle, and heat exchanger temp readouts

Dedicated pump control switches

Dual cart mounted electrical service panels

Ships fully assembled and ready to brew

1 bbl final batch size

20% kettle headspace

2.5mm kettle wall thickness

2B Mill Finish

1” process piping

1” ID butterfly valves, sight glasses, and TC gaskets

1 Square Meter Heat Exchanger surface area

74" width x 52" height x 40" depth

Production Order: All orders will be produced, fulfilled, and shipped in the order that they are received.

Shipping: All orders will ship LTL common carrier freight with liftgate service included. Buyer shall be responsible for receiving, inspecting, testing, storing, installing, starting up and maintaining all goods. Installation and startup of goods should only be completed by an experienced technician conforming to all manufacturer recommendations. Improper installation or start up procedures may result in damage to personnel, equipment or building. Vibration that occurs during shipping may loosen some of the electrical connections such as those at the circuit breakers, motors, motor starters, pumps, contacts and heating elements. All high amperage electrical connections should be thoroughly tightened prior to start up. Failure to tighten loose connections may result in excessive heat buildup on the electrical components resulting in damage to the component, equipment or even the building. The Seller expressly disclaims any damages or losses of any kind resulting from loose electrical connections.